Let’s turn up the heat: How heat application impacts the taste of coffee

Roasting speciality coffee is simple math: We apply heat to green coffee beans to develop the tastes and flavours. Or is it?

Different roasting methods transfer heat in different ways. The specific heat transfer method as a function of time determines which flavours, aromas and unique attributes are developed.

Let us explore these differences by discussing the types of coffee roasters available, how heat is transferred, and what the roasting process does to the bean.

Coffee roasters: drum, electric and fluid bed roasters

Drum Roasters

This type of coffee roaster consists of a rotating drum that agitates the coffee beans. The drum rotates while the beans inside are heated, typically by means of a gas burner, while a fan draws hot air through the beans. Drum roasters with thin-walled drums may supply more heat to the beans that may distort the taste, whereas a double-walled drum may result in a more softer, more even application of conduction heat to the beans. In most drum roasters, around 30% of the energy is transferred via conduction heating (more in single-walled drums), while the remainder and majority of the energy is transferred to the beans by means of convection heating.

Significant to note, is that the cooling-down process is quick and controlled though a dedicated fan and a stirring motion of specially designed agitators.

Electric Roasters

Electric roasters are not typically suited as industrial machines. They are more focused on home or sample roaster machines.

From a practical standpoint, getting an electric roaster up and running can be quite easy. You do not require a gas fitter and permits. when you have the ventilation done and sorted, it is plug and play. The key benefit with an electric roaster is obviously not having to have a gas installation.

Another major difference is the heating and cooling time of an electrical roaster: on an electric roaster the heating element needs time to cool down when you lower the temperature. This is because the electric supply to the heating element is cut, but the element itself is still hot. The same goes for the increase in temperature; an electric element needs time to heat up to reach your temperature setpoint.

Electric roasters therefore is slow to respond to inputs, making them less ideal for profile roasting. More often than not, electric roasters have a 30 minute batch turn-around time from start to finish, while gas-powered roasters should be able to roast a batch in less than half that.

Fluid-bed roasters

Fluid-bed roasters relies on large fans to suspend the beans in a stream of hot air. Even though air roasting methods have been around since the 1970s, only a small percentage of coffee served around the world today is air roasted.

As the hot air flows through the roaster, the force lifts the beans into the air, causing them to “float”. This effectively means the coffee beans are resting on a “bed” of heated air, which is where fluid-bed roasting gets its name from.

Since the hot air is blowing from beneath, there is no direct heating of metal. However, the beans have to be in some form of container, and its sides will get as warm as the circulating air. Therefore, it is not purely convection roasting, but it is definitely more convection heating compared to drum roasting. Air roasters can use electric elements or gas for heating the air.

According to an article from Coffeetech.com “Air roasters require a high-pressure flow of air…In air roasters, the air has to physically lift the coffee to get through. This means that air roasters require blowers that can deliver high pressure. “The result, a very loud roasting environment not suitable for in-shop roasting. Operators often work with ear protection to prevent damaging their ears from the noise of the roaster.

Heat transfer and getting to the umph!

Electricity or gas

As previously mentioned, electric roasters are slow responding systems; they take longer to heat up or cool down and have limited controllability during roasting. Think about an electric stove plate: it takes a while for it to heat up, and when you turn it off, it takes a while for it to cooldown. The distinct benefit of roasting with gas is therefore the amount of control it offers the roast master.

Having said that, there are all kinds of new roasters coming out with halogen lamps which are much better faster responding. Halogen lamps give you instant heat output, whereas electrical elements do not achieve that. With a bigger coffee roaster, you will also need 3-phase electricity supply.

If anyone tells you that electric roasters do not produce smoke, think again! It is not the element that produces smoke, but rather the coffee beans. Green beans contain 11-14% moisture and, when roasted, create significant amounts of visible smoke, odour and VOCs (Volatile Organic Compounds). As with a gas stove, the burner itself produces almost no emissions and most professional machines will have low NOX burners to boot.

Convection versus conduction heat

In the roasting process, convection heat is from air to bean, and conduction heat is from surface to bean.

For example, if you fry meat in a pan, your meat will become crispy on the surface with a smoky, robust taste. This is an example of conduction heat transfer: you have a high heat transfer in a short period of time as the heat is directly transferred from the hot pan to the meat.

On the other hand, if you cook that same meat in your convection oven, it will have to stay in the oven for longer because convection heat is a softer, more even application of heat. This results in more evenly cooked food with no burnt spots as we see when grilling meat in a pan.

We already know that air is a bad heat conductor. To illustrate this, think about the difference between putting your hand into a convection over for one second vs touching a hot pan on a stove top for the same period of time (kids, do not try this at home). The pan is far hotter to the touch because heat is transferred via conduction.

Now, let us apply this theory to coffee roasting: even though air may not be a good heat conductor, it envelops the entire bean surface, as it roasts the bean from all sides at the same time. It

At Genio, we use the best of both worlds and combination of convection and conduction heat in our coffee roasting process to achieve a more layered coffee profile in a shorter time frame.

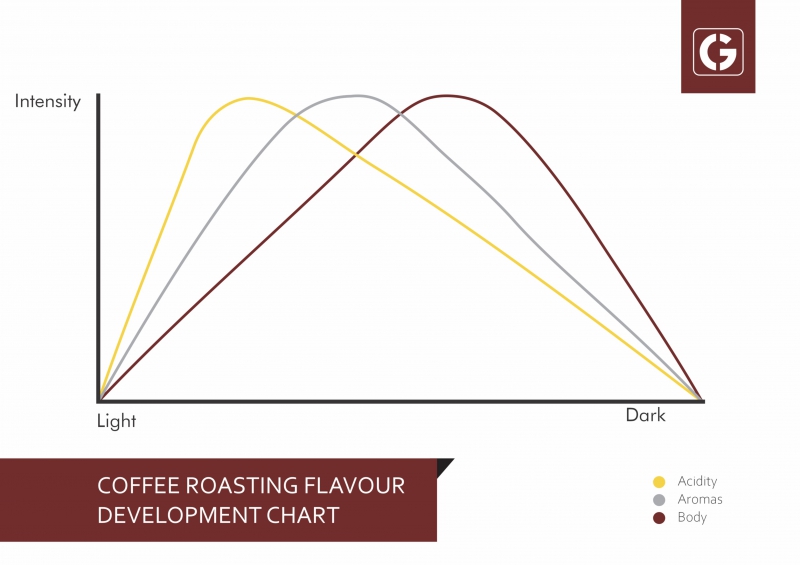

Acidity-Body Curve

Back in the 1980s, they used ultra-fast roasting, sometimes within a few minutes only, to roast coffee beans from green to brown. This practice was driven by the concept of the industrialisation of processes, where they wanted to finish the roast as quick as possible. Quality took a back seat during this era. The result: a bitter cup with high solubility but little flavour or aromas because the Maillard Reaction had no time to develop flavours and aromas. The industry soon came to realise that the taste did not appeal to coffee drinkers and this method of roasting fell away.

Refer to the Acidity-Body Curve (Figure 1). The curve explains that the roast will first peak for acidity and thereafter it will peak for body. When you light-roast beans you have a more acidic coffee, and when you dark-roast beans you have more body.

Remember that, in the coffee world, acidity is not bad. According to numerous sources acidity is not a sour sensation, which is a taste defect, nor should it be excessively drying or astringent. “At best it (acidity) is a sweetly tart vibrancy that lifts the coffee and pleasurably stretches its range and dimension. Acidity can be delicate and crisp, lush and rich, powerfully tart but sweet, or backgrounded but vibrant, to cite only a few positive ways to characterise it” (source: Interpret Coffee).

The holy grail is to get that combination of acidity and body. Because, even the most delicate beans also need some form of body. One solution is to blend coffees with more body together with coffees with floral notes so to get the best-of-both worlds. As a footnote, there is nothing wrong with blending as long as you do it for the right reasons – another story for another day.

The best way to achieve the balance between acidity and body is to have more control over your heat transfer, both convection and conduction heating. Using sensitive heat and sensors positioned in critical areas inside the roaster’s drum, the roast master takes back the control of the profile roasting and achieve a more desired end product.

Profile roasting: proof is in the cupping

So, what is the difference between fluid-bed roasting and drum roasting? Which one is better, and can you tell the difference? The answer is: quite likely yes, you will taste the difference. Depending on the temperature profile, the flavours will be different in the cup because the heat transfer profile is different. And, ultimately, the cup profile is the only real proof of the best roasting style for your preference. In my experience, most people prefer a more balanced cup with acidic, more fruity flavours as well as body present in the cup. Drum roasters will always have a more balanced cup because of the fact that both convection and conduction heat transfer was used to develop the flavour profile. Don’t believe me? Try it for yourself by contacting Genio Roasters for a demo!

#GenioForLife

Neil